CAD/CAM Technology and Esthetic Dentistry: A Case Report

Advances in dental materials as well as in computer technology have made CAD/CAM-fabricated restorations not just possible in dentistry but plentiful. When using CAD/CAM systems, operators can fabricate restorations from several materials, including ceramics, metal alloys, and various composites. This case report describes the replacement of a porcelain-layered zirconia-based (coping) crown on a left lower cuspid that presented with a veneering ceramic chipping on a lithium-disilicate CAD/CAM-fabricated crown. It demonstrates how all-ceramic systems offer a promising alternative in the restoration of anterior teeth.

Over the past two decades, dentistry has seen the development of many new all-ceramic restorative systems. The drive for such materials and restorative techniques has been precipitated by patient expectations for excellent esthetic results and also by concerns about the biocompatibility of metals intraorally.1,2 The combination of advancements in dental materials as well as in computer technology has made computer-assisted design/computer-assisted manufacturing (CAD/CAM)-fabricated restorations possible—and plentiful—in dental clinics. As a result, all-ceramic restorations have become both a necessary alternative to metal–ceramic systems, as well as a preferred choice. These new all-ceramic systems can use a monolithic glass–ceramic material (eg, IPS e.max® CAD, Ivoclar Vivadent, www.ivoclarvivadent.com), whereas others utilize layered porcelain over the core.

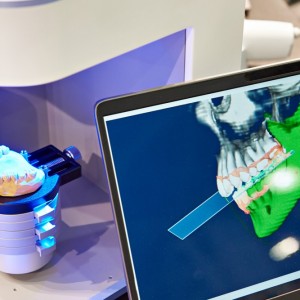

CAD/CAM technology was introduced to dentistry in the early 1980s, and since then, it has evolved in two directions. One is the intraoperatory (chairside) application for a one-appointment restoration fabrication and insertion using prefabricated ceramic monoblocks. The major impediment is its high initial cost, which can make it difficult for many dental offices to adopt the technology. The other direction is the development of systems for commercial production centers and dental laboratories.3 Regardless of the system (chairside or commercial laboratory), all CAD/CAM units have three functional components: data capture or scanning to capture and record data about the oral environment (eg, tooth preparation, adjacent teeth, and occluding tooth geometry); CAD to design the restoration to fit the preparation and to perform according to conventional dental requirements; and CAM to fabricate the restoration.

CAD/CAM Systems

An example of a chairside system is the computer-assisted CERamic REConstruction system (CEREC®, Sirona Dental Systems, www.sirona.com), which was the first operational CAD/CAM system to be used in the dental office.5 The system has evolved through a series of software and hardware upgrades since its introduction to the dental marketplace.6 CEREC uses an intraoral digital 3-dimensional (3-D) scanning device (digitizer) that takes a 3-D image of the tooth preparation. It uses infrared waves, which are sent down to the preparation and back to the camera to measure heights of the tooth structure, adjacent teeth, and surrounding tissue. Nontoxic, titanium-dioxide powder is applied to the preparations and neighboring teeth to ensure the waves bounce back to the camera in a uniform manner. Since dentin, enamel, and gingiva absorb the infrared waves at different rates, an unpowdered field would reflect the waves inconsistently and result in a picture that the CEREC 3-D software cannot use.

Another example of a chairside system is the E4D (E4D Technologies LLC, www.e4d.com), which uses an intraoral digitizer laser—which requires no powder—to capture the teeth preparations.

Authors: Gildo Coelho Santos Jr., DDS, MSc, PhD; Leendert (Len) Boksman, DDS, BSc; and Maria Jacinta Moraes Coelho Santos, DDS, MSc, PhD

Read the full article here: https://www.aegisdentalnetwork.com/cced/2013/12/cad-cam-technology-and-esthetic-dentistry-a-case-report

Related articles

Related articles

Products 01 September 2025

Dentsply Sirona Releases Innovative CAD/CAM Zirconia Block and Abutment Resin Cement

The CEREC Cercon 4D Multidimensional Zirconia Abutment Block combines high strength with aesthetics for both hybrid abutments and hybrid abutment crowns.

Restorative dentistry 01 July 2025

Advances in CAD/CAM Technology for Chairside Restorative Dentistry: A Workflow Analysis

Chairside CAD/CAM technology has revolutionized restorative dentistry, offering streamlined workflows and improved patient outcomes.

News 03 February 2025

Directa USA is excited to introduce Ceramir CAD/CAM BLOCKS, a revolutionary bioceramic material that marks a groundbreaking advancement in prosthetic materials and embodies the spirit of...

Ceramir CAD/CAM BLOCKS are a breakthrough in the CAD/CAM materials market. Manufactured by using a special advanced patented laser sintering technology, the new Ceramir CAD/CAM BLOCKS have a unique...

Factors such as increasing demand for cosmetic dental procedures, increased implant usage, growing dental tourism, an aging population and global economic expansion are driving the market growth.

Read more

Read more

Much like EMTs rushing to the scene after an accident, stem cells hurry to the site of a skull fracture to start mending the damage. A new finding has uncovered the signaling mechanism that triggers...

Products 05 November 2025

SimplyTest has launched a groundbreaking saliva-based test to detect high-risk strains of oral human papillomavirus (HPV), a major cause of oropharyngeal cancers.

News 05 November 2025

Perimetrics, Inc., a dental technology company pioneering quantitative diagnostics, announced today that the U.S. Food and Drug Administration (FDA) has granted clearance for the InnerView...

News 05 November 2025

On October 15, open enrollment for Medicare began nationwide. Hundreds of thousands of seniors in New Jersey will once again face the challenge of finding the right Medicare coverage, including the...

Digital Dentistry 04 November 2025

Digitalisation is an expanding field in dentistry and implementation of digital teaching methods in dental education is an essential part of modern education.