Digital approach to replicate aesthetic and functional parameters in complete implant rehabilitation

Authors: C. Monaco, N. Ragazzini, L. Card, E. Evangelisti

The introduction of digital technologies in implant-prosthetic dentistry has allowed an improvement in the predictability of clinical results, the reduction of clinical and laboratory procedures. Thanks to the use of a fully digital technique (FDT), the clinician has the possibility to perform the therapy in a prosthetically guided manner, to realize the temporaries even before implant insertion, to perform a guided surgery with or without opening a flap, to reduce therapeutic time and potentially related costs.

The purpose of this study is to describe the application of FDT in a case of complete rehabilitation on implants.

MATERIALS AND METHODS

A total edentulous patient with incongruous prosthesis comes to our attention with the request for a complete prosthetic rehabilitation. For an optimal case we have chosen to apply the completely digital technique. After examining and revising the aesthetic and functional parameters, the pre-existing total prostheses were duplicated to produce twice radiographic images useful for the Cone Beam exam.

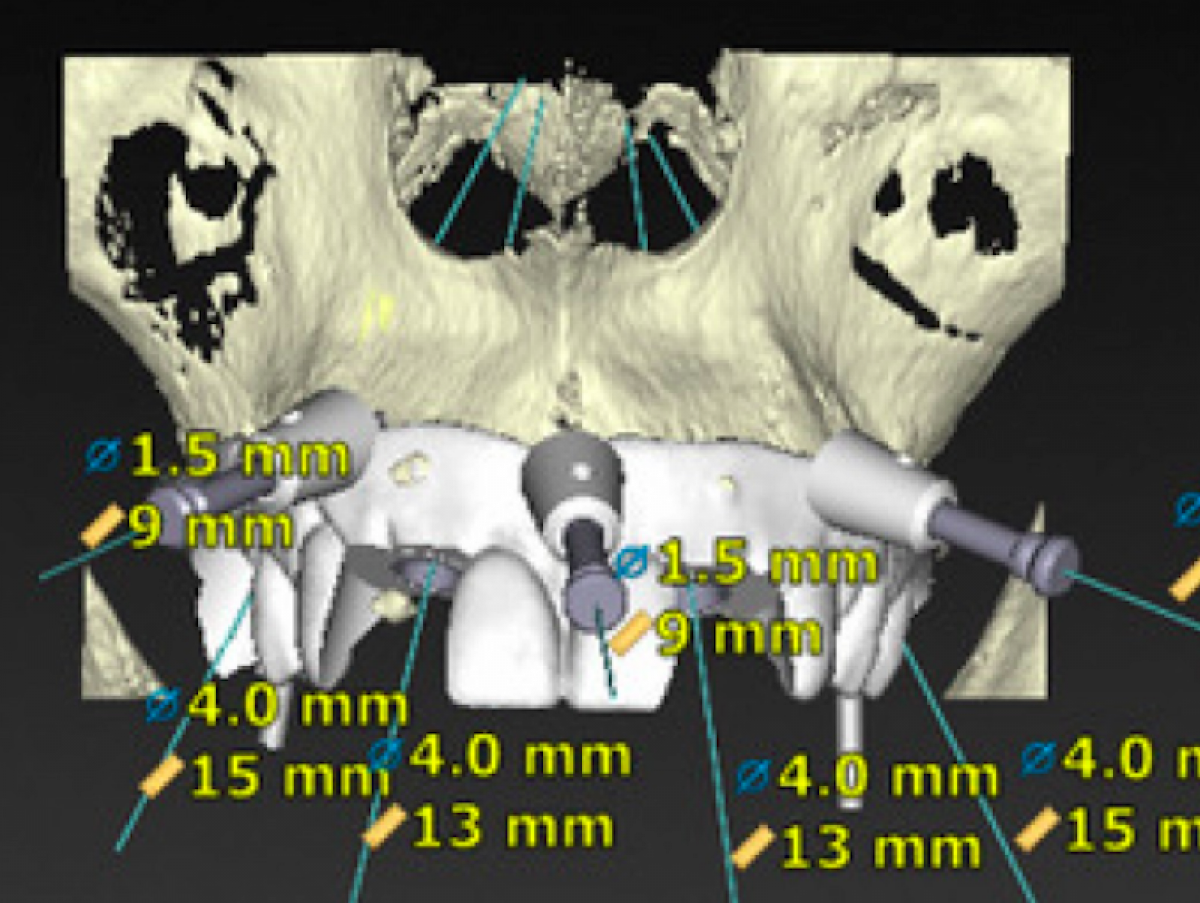

The X-ray images were studied using the Nobel Guide, later due to two implant surgeries (Figure 1).

Prior to surgery, the provisional prostheses were digitally designed based on implant planning and made by milling to CAD / CAM. The surgery day, the implants were inserted using surgical templates and, subsequently, the provisional prostheses were fixed to the provisional abutments, finished and subjected to immediate loading.

Four months after surgery, three sets of intra-oral fingerprints were performed to collect information about the provisional prostheses (STL1), the three-dimensional implant position (STL2), and the soft tissue architecture in contact with the prostheses. All impressions were obtained using an intraoral scanner with wavefront technology (True Definition Scanner - Lava Cos, 3M ESPE, St. Paul, MN, USA) after applying the powder for scans (3 M ESPE , Seefeld, Germany).The first set of intraoral impressions (STL1) was performed by scanning the temporaries still screwed to the implants and, together with the prostheses, the surrounding gingival tissues were scanned. In this phase the arches were first scanned separately then in maximum intercuspidation so as to obtain both the information regarding the functionalized vertical dimension, and the information on the shape of the dental elements and their position.

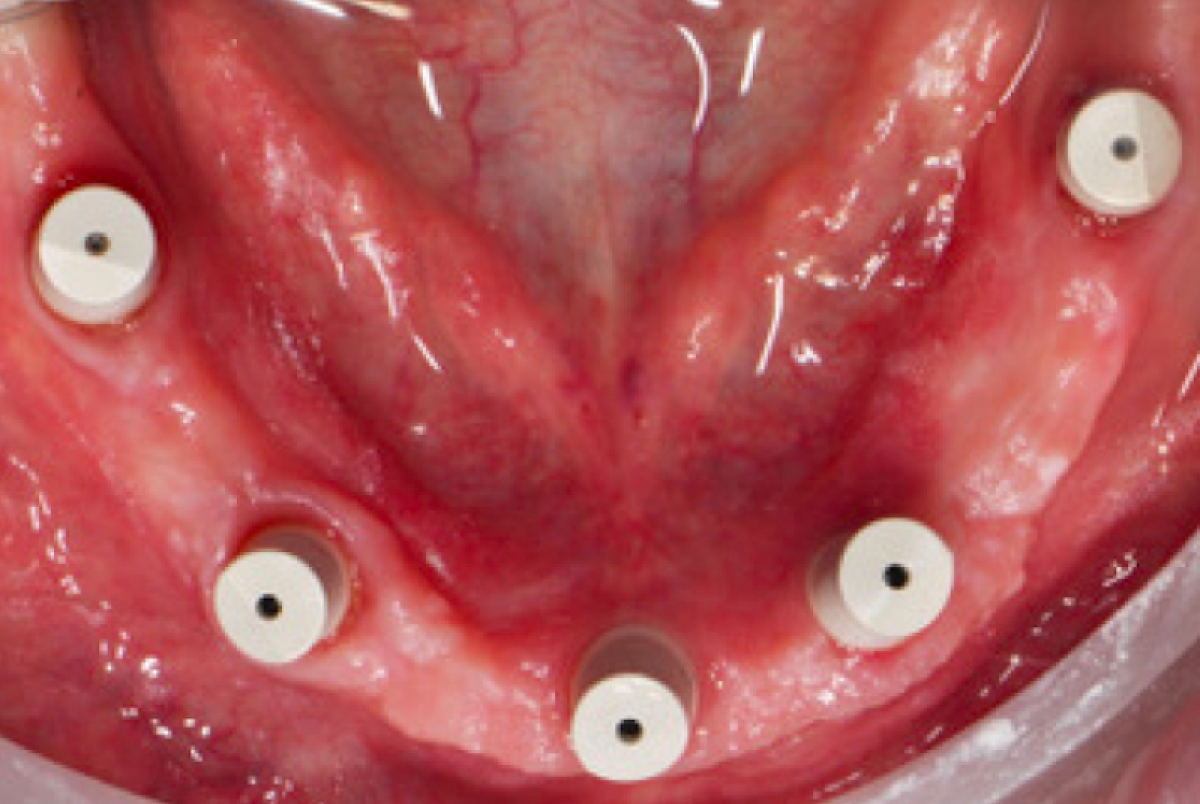

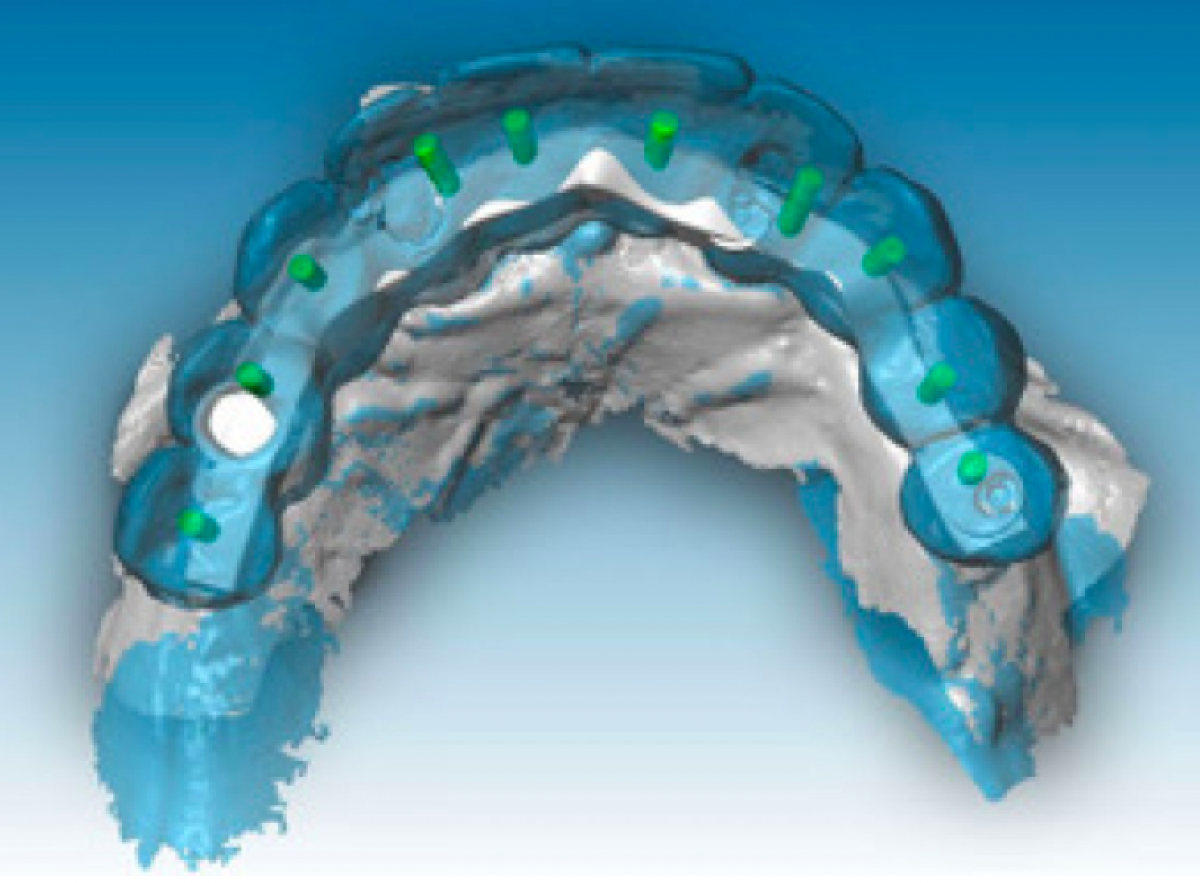

Thereafter, the provisionals were removed from the standard implants and scanbodies (Elos Medtech AB, Lidköping, Sweden) were screwed to the implants (Figure 2).

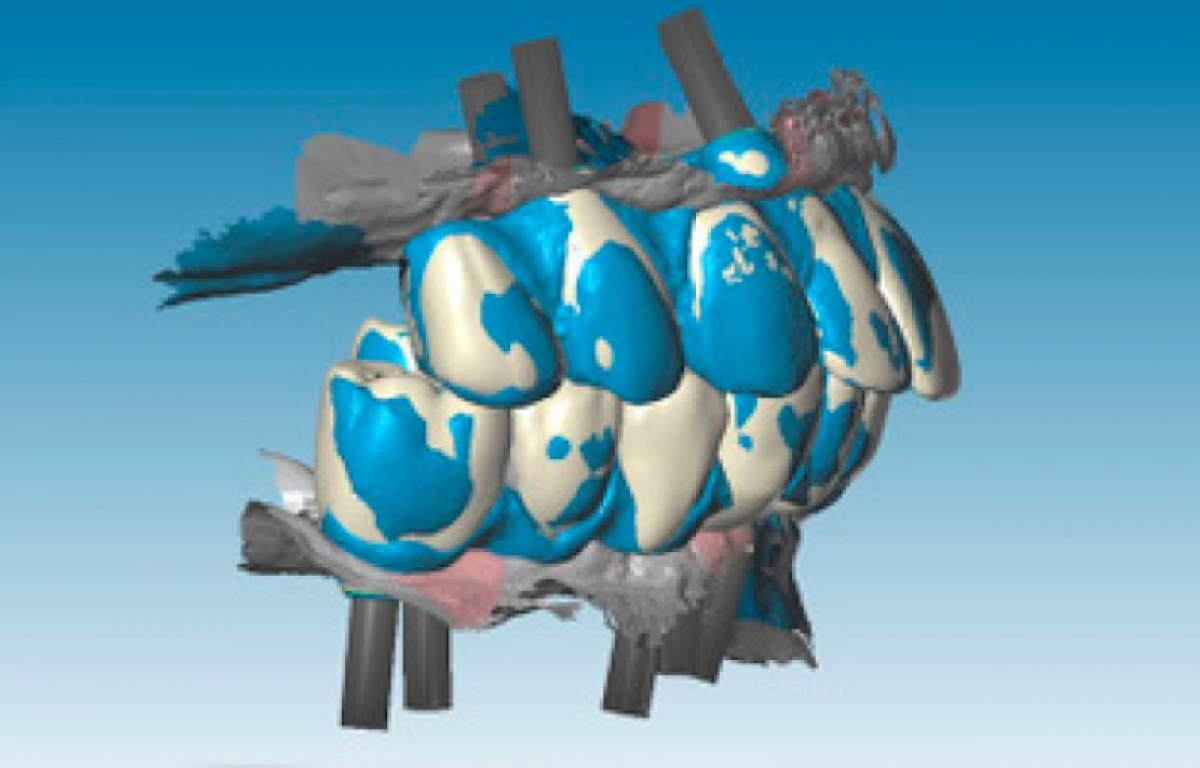

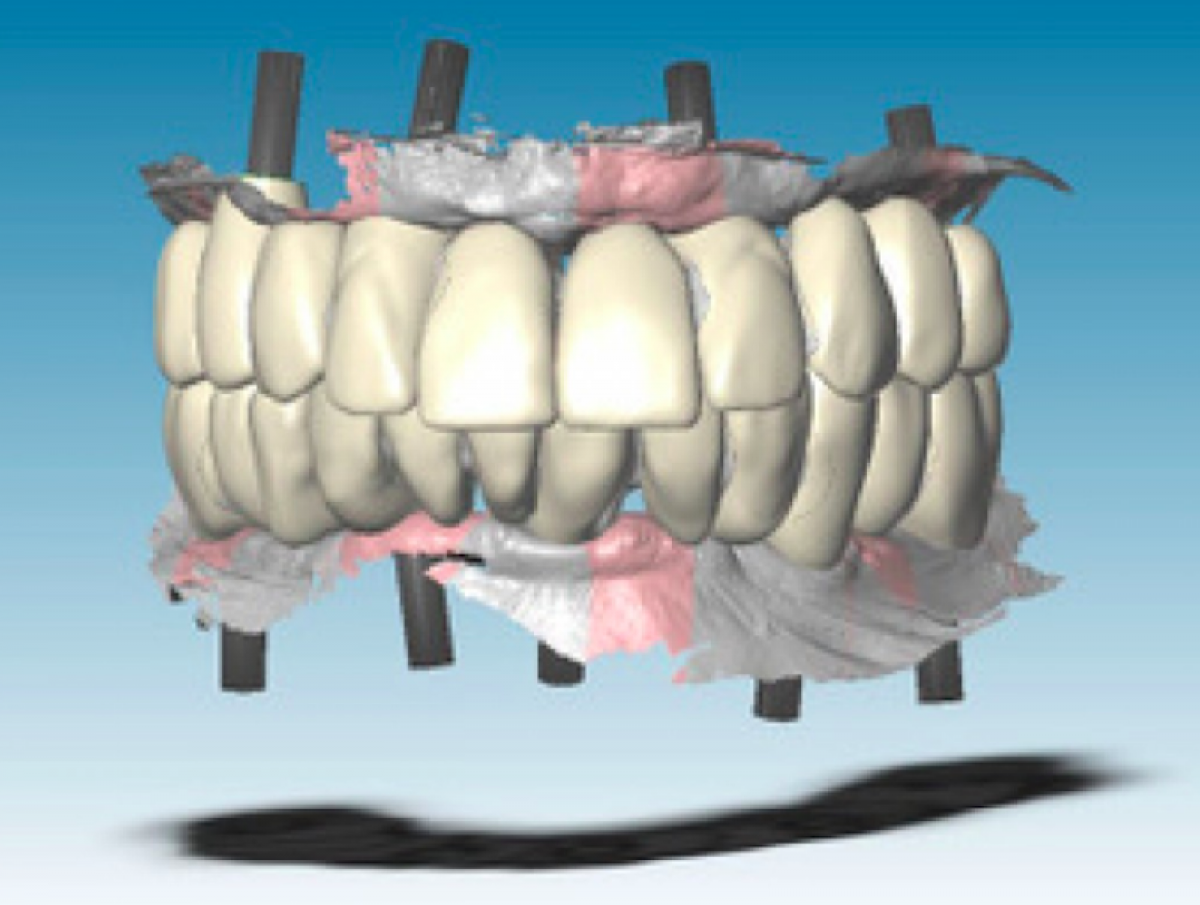

In this phase it is not possible to collect information about the occlusal relations between the two arches since there is no occlusal stop or stop. Finally, to collect the negative information about the soft tissues adjacent to the prostheses (implant emergence profile and gingival anatomy underlying the pontic elements), the upper and lower provisional were scanned outside the mouth and the third set of impressions ( STL3) was thus obtained. The three series of impressions STL1, STL2, STL3 were then imported into Geomagic Studio 12 software (3D Systems, Rock Hill, SC, USA) and combined using a specific automatic coupling algorithm. Since the gingival tissues scanned in the STL1 and STL3 series were the same, the software identified a good automatic coupling. Thereafter, the STL2 impressions were also coupled thanks to the correspondence between the form of the provisionals acquired in STL2 and STL3.Through the CAD union of the different fingerprints, a single file was obtained, called STL4, which contained the following information: three-dimensional scanbody position, soft tissue architecture, occlusal parameters and esthetic characteristics. The STL4 file was then imported into dental software (Dental Wings, Montréal, QC, Canada) to automatically and certify the position of the implants starting from the scanbodies (Figure 3).

The STL4 file, which at this point represented the virtual master model, was used to create two stereolithographic master models with the implant analogs. Also starting from the STL4 file, two aluminum bars (one for the upper and one for the lower one) with integrated implant connections (Figure 4) have been designed and made to CAD / CAM.

The two bars were screwed to the patient's implants to test the passivity and then to validate the STL2 fingerprints (Figure 5).

Similarly, two resin prototypes were designed and produced to evaluate occlusal and esthetic parameters on the patient (Figures 6, 7).

Once all the occlusal, esthetic and implant position parameters have been checked, the final metal substructures have been designed and manufactured in CAD / CAM.

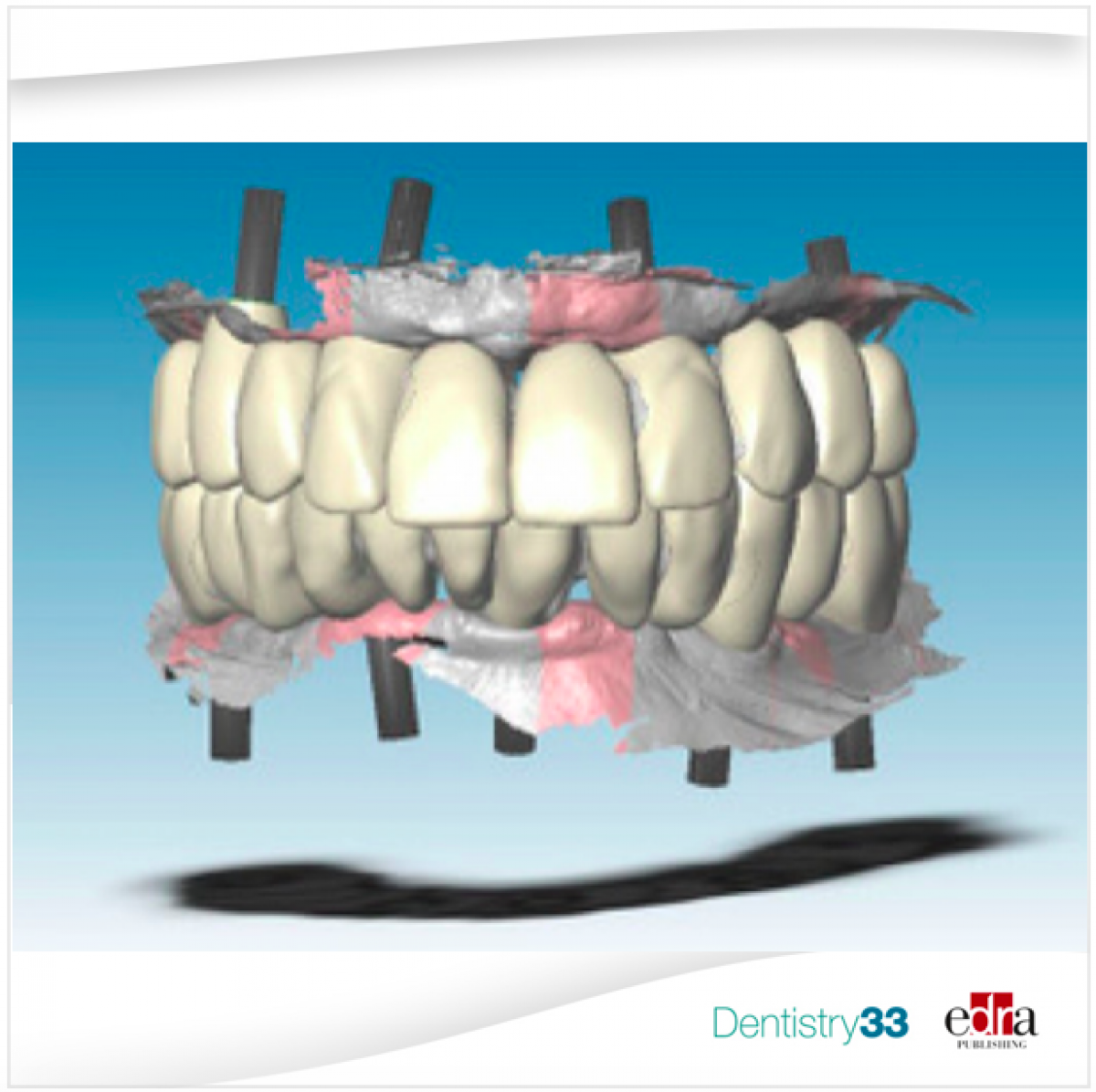

The digital design procedure was facilitated by the presence of the virtual wax-up of the final prosthesis (based on the form of functionalized temporaries) on STL4. This allowed the technician to draw the anchoring pins of the substructure based on the position of the teeth in the prostheses (Fig. 8).

The substructures were milled to CAD / CAM with a 5-axis system using a grade 5 titanium alloy. The finished substructures were tested on the patient by the Sheffield test and radiographic control (Fig. 9).

The definitive prostheses were then finalized using conventional techniques and the teeth were chosen following the digital waxing (Fig. 10).

The finished dentures were screwed to the implants with a torque of 35 Ncm and the occlusal contacts were individually controlled with 20 micron articulation paper. Finally, every single element was checked with an 8 micron Shimstock (Fig. 11).

CONCLUSIONS

This fully digital protocol has proven to be a reliable method for transferring the characteristics of temporary prostheses and gingival anatomy to definitive prostheses. The acquisition and processing of data was performed successfully in four phases: intra and extraoral scan of the provisionals, impression of the scanbody screwed to the implants and, finally, the digital combination of the impressions. To test the degree of accuracy of the impressions and functional / aesthetic parameters, aluminum CAD / CAM bars and resin prototypes were produced and clinically tested. This digital approach allowed to reduce laboratory and treatment time, allowed the verification of aesthetic and functional parameters and facilitated the design of the final substructure based on virtual waxing.

For additional informations:

A fully digital approach to replicate functional and aesthetic parameters in implant-supported full-arch rehabilitation

Related articles

Related articles

News 01 April 2024

Revolutionize Your Practice: Explore Dentsply Sirona’s New Digital Dentistry Course Series

Dentsply Sirona’s new indirect restorative course series covers a range of topics, including the latest advancements in digital technology, the science behind material selection, incorporating new...

Products 25 March 2024

Desktop Health Launches ScanUp Digital Dentistry Adoption Subscription Program

Desktop Health announced the launch of ScanUp, a new program for dentists designed to help simplify adoption of digital technologies to improve practice efficiency and patient care.

Intra-oral scanners (IOS) continue to gain popularity in the dental field, replacing traditional impression taking and related technology. Although there are numerous studies in the literature...

News 25 September 2023

Dentsply Sirona expands DS Academy clinical education with launch of new online campus

Dentsply Sirona is expanding its digital education opportunities with a new DS Campus online. Dental professionals will find a range of on-demand content covering topics in implant dentistry,...

USA 21 September 2023 - 23 September 2023

Early Bird pricing available through July 15

This year’s "Ultimate Experience in Digital Dentistry" will be a special learning opportunity with two live procedures for participants to observe and learn from. Renowned experts Drs. Mark Ludlow...

Read more

Read more

Editorials 16 April 2024

Dr. Kyle Vining Earns Hartwell Foundation Award to Study Childhood Leukemia

Every year, thousands of American children are diagnosed with acute lymphoblastic leukemia (ALL), the most common form of childhood cancer. The disease begins in bone marrow, when immature cells...

News 16 April 2024

The UF College of Dentistry notched a record turnout for its annual celebration of research – Spring Synergy – on Friday, March 29 at the HPNP Auditorium

Products 16 April 2024

Glidewell recently announced a rebrand of its flagship Hahn Tapered Implant System, now known as the Glidewell HT Implant System.

Market 16 April 2024

Zentist Launches Cavi AR, an RCM Software for Dental Insurance AR & Claims Management

Zentist, the leading cloud-based insurance Revenue Cycle Management (RCM) software for U.S. dental groups, proudly announces the introduction of Cavi AR, an additional innovative solution that is...

News 16 April 2024

Standard Dental Labs Sets Sights on Expansion Following Strong FYE 2023 Performance

Costas, Inc., operating as Standard Dental Labs Inc., a renowned name in the dental industry, is pleased to announce the filing of its annual report for the fiscal year ending 2023 on April 10th,...